Explore our portfolio of precision coating equipment, optimized for high efficiency coating of Polyimide (PI) and Photoresist (PR) applications in FOPLP processes. With over 30 years experience in slot die coating of PI and PR materials, APS empowers manufacturers to meet the demands of next-generation electronics. Stay informed with industry insights, technological breakthroughs, and market trends shaping the future of semiconductor packaging.

Partner with APS to drive innovation in Fan-Out Panel Level Packaging.

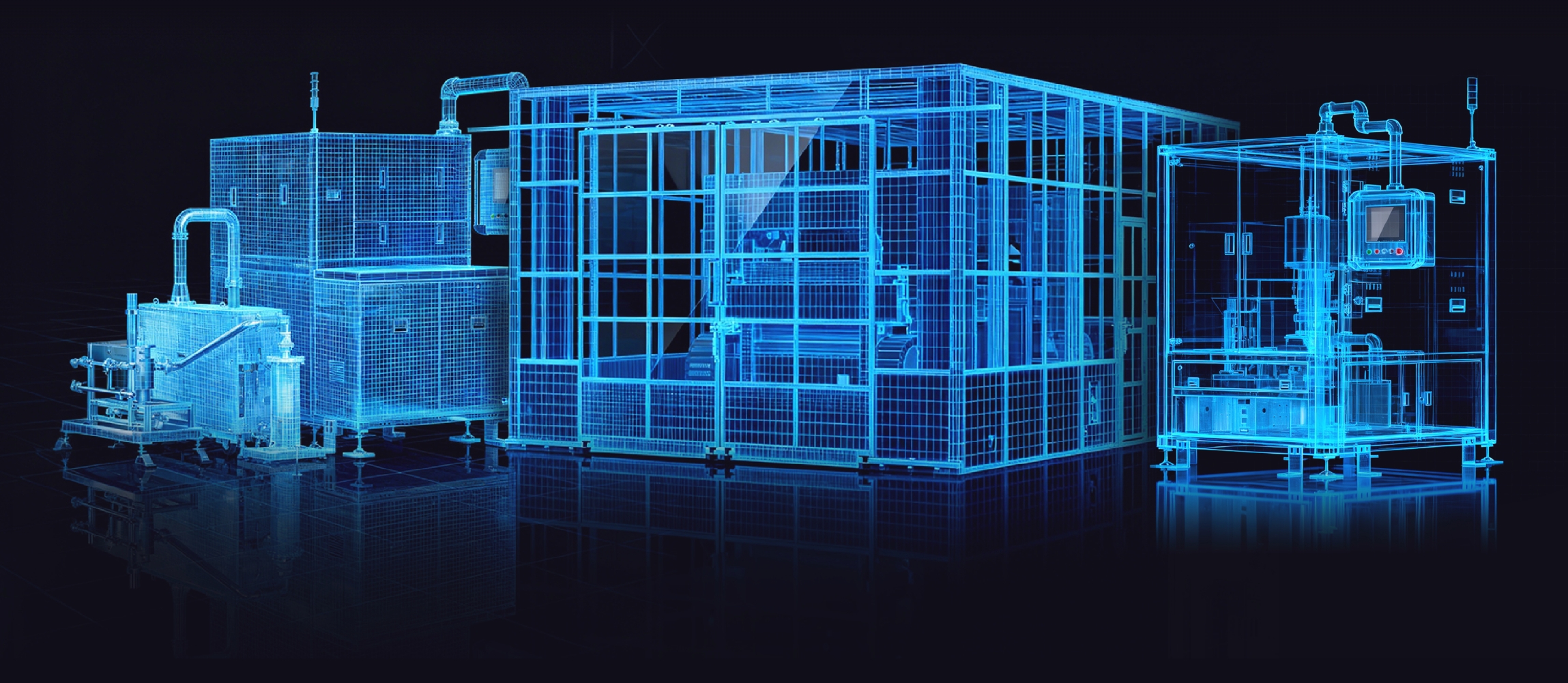

APS offers a new line of Coating Equipment specifically geared towards Panel Level Packaging applications. These coaters are designed to primarily process Polyimide (PI) and thick Photoresist (TFT) materials used for packaging applications. These systems include slot die coater (single or dual gantry), multiple vacuum hotplates (HVCD) for high throughput processing, and automated substrate handling. APS PLP solution also includes very specific features to address challenges encountered with PLP processing, including handling of significantly warped panels, and material de-gassing system to eliminate microbubbles which may be generated in the process material, particularly PI.

|

Items |

Detail |

|

Substrate size |

300*300mm, 515*510mm, 600mm*600mm |

|

Substrate type |

Glass, CCL, Molded substrate |

|

Scope |

Coater, (H)VCD, Hot-Plate, Cold-Plate, EFEM(Robot System), IN/OUT Conveyor ERS module (Edge Remove System after coating), Cleaner, Developer etc |

|

Coating Liquid |

PI(Polyimide), PR(Photoresist), TBDB(Temporally Bonding Debonding Film) |

|

Viscosity |

1 – 10,000 cp |

|

Options |

Dual Coating heads, Glass warpage cramp, Low / High viscosity head, Heat VCD, IN / Off Line design |

|

Application |

Semiconductor Advanced Panel Level Package, Glass core, RDL Interposer, Organic Interposer, FOPLP, 2.1D, 2.3D, 2.xD |